There are many ways to reduce price and manufacturing lead time for large volume PCBs and this is always Pandawill’s objective.

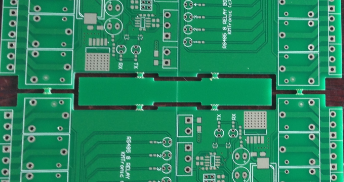

One process that has historically created a bottleneck in PCB production with circular or complex outline circuits is the relatively slow routing stage. Often a combination of scoring and routing can be a very effective way of reducing the process time on the routing machine and therefore reduce cost.

Punching does attract a large initial one off tooling charge compared to conventional manufacture, but conversely the cost of each circuit board and panel manufactured will be proportionaly cheaper based on the reduction in process time required at the mechanical stage.

For large volume requirements, the circuit board cost reduction can very quickly justify the tooling charge.