Cheap PriceList for Kb Laminate Pcb Manufacturer - 4 layer rigid flex circuit board for automotive – Pandawill

Cheap PriceList for Kb Laminate Pcb Manufacturer - 4 layer rigid flex circuit board for automotive – Pandawill Detail:

Product Details

| Layers | 4 layers rigid, 2 layers flex |

| Board thickness | 4 layers rigid, 2 layers flex |

| Material | Shengyi S1000-2 FR-4(TG≥170℃) + Polyimide |

| Copper thickness | 1 OZ(35um) |

| Surface Finish | (ENIG 3μm) Immersion gold |

| Min Hole(mm) | 0.22mm |

| Min Line Width(mm) | 0.15mm |

| Min Line Space(mm) | 0.18mm |

| Solder Mask | Green |

| Legend Color | White |

| Packing | Anti-static bag |

| E-test | Flying probe or Fixture |

| Acceptance standard | IPC-A-600H Class 2 |

| Application | Optics device |

Introduction

Rigid-flex PCB means hybrid systems, which combine the characteristics of rigid and flexible circuit substrates in one product. Whether in medical technology, sensors, mechatronics or in instrumentation, electronics squeezes ever more intelligence into ever smaller spaces, and the packing density increases to record levels again & again. Using flexible PCBs and rigid-flex printed circuit boards, whole new horizons open up for electronic engineers and designers.

Advantages of rigid-flex PCB

l Reduction of weight and volume

l Defined characteristics of the circuit systems on the circuit board (impedances and resistances)

l Reliability of the electrical connections due to reliable orientation and reliable contacts as well as savings on connectors and wiring

l Dynamically and mechanically robust

l Freedom to design in 3 dimensions

Materials

Flexible base material: Flexible base material consists of a foil made of flexible polyester or polyimide with tracks on one or both sides. PANDAWILL uses polyimide materials exclusively. Depending on the application, we may use Pyralux and Nikaflex made by DuPont and the glueless flexible laminates in the FeliosFlex series made by Panasonic.

Apart from the thickness of the polyimide, the materials mainly differ in their adhesive systems (glueless or on epoxy or acrylic basis) as well as in the copper quality. For comparatively static bending applications with a low number of bend cycles (for assembly or maintenance) ED (electro-deposited) material is adequate. For more dynamic, flexible applications RA (rolled annealed) materials must be used.

Materials are selected on the basis of the product and production specific requirements, and the datasheets of the materials used can be requested as required.

Adhesive systems: As a bonding agent between the flexible and the rigid materials, systems using adhesive on an epoxy or acrylic basis (which is still capable of reacting) are used. The options are as follows:

Composite film (polyimide film coated on both sides with adhesive)

Adhesive films (adhesive systems poured onto a paper base and covered with a protective film)

No-flow prepregs (glass mat/epoxy resin prepreg with very low resin flow)

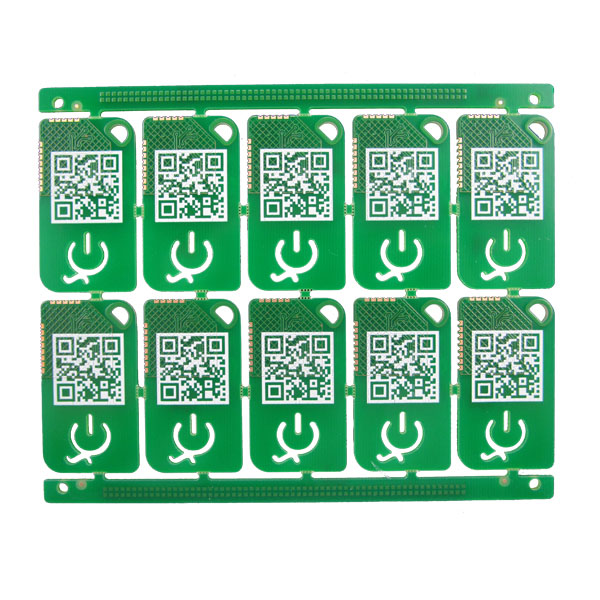

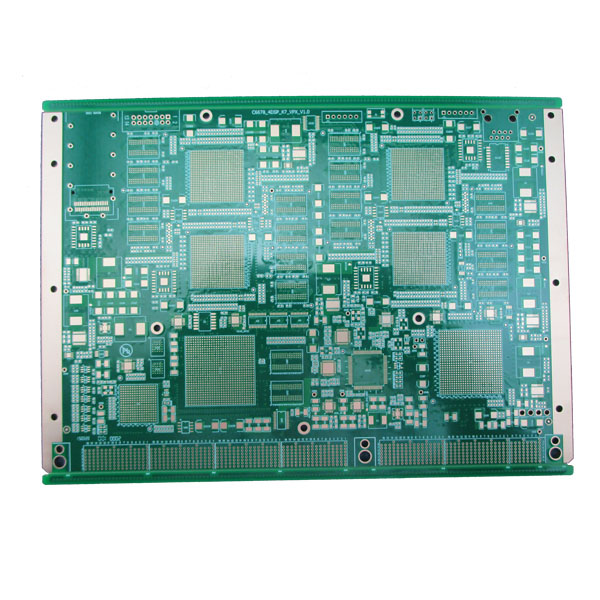

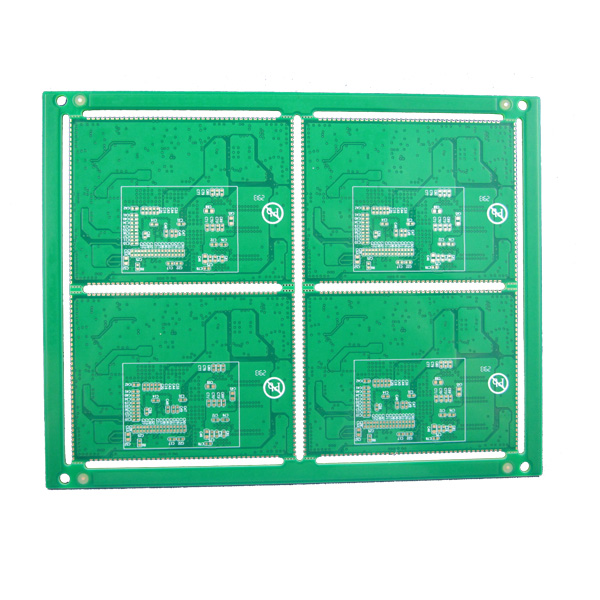

Product detail pictures:

Related Product Guide:

High-quality comes 1st; support is foremost; business is cooperation" is our small business philosophy which is regularly observed and pursued by our organization for Cheap PriceList for Kb Laminate Pcb Manufacturer - 4 layer rigid flex circuit board for automotive – Pandawill , The product will supply to all over the world, such as: Netherlands, Serbia, Benin, Due to the stability of our items, timely supply and our sincere service, we are able to sell our merchandise not only over the domestic market, but also exported to countries and regions, including the Middle East, Asia, Europe and other countries and regions. At the same time, we also undertake OEM and ODM orders. We will do our best to serve your company, and establish a successful and friendly cooperation with you.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!