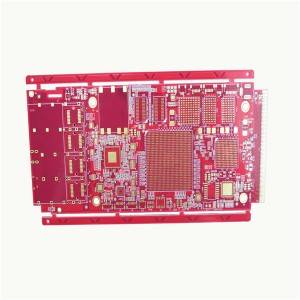

14 layer Panasonic MEGTRON4 PCIE board for Intel

Product Details

| Layers | 14 layers |

| Board thickness | 1.60MM |

| Material | Panasonic MEGTRON4 R-5725 |

| Copper thickness | 1 OZ(35um) |

| Surface Finish | ENIG finish |

| Min Hole(mm) | 0.20mm; via plugged with resin |

| Min Line Width(mm) | 0.13mm |

| Min Line Space(mm) | 0.13mm |

| Solder Mask | TAIYOPSR4000 RD5 birght red |

| Legend Color | White |

| Impedance | Single Impedance & Differential Impedance |

| Packing | Anti-static bag |

| E-test | Flying probe or Fixture |

| Acceptance standard | IPC-A-600H Class 2 |

| Application | PCIE ICT industrial device |

Introduction

Multilayer

In this section, we would like to supply you with basic details about the structural options, tolerances, materials, and layout guidelines for multilayer boards. This should make your life easier as a developer and help to design your printed circuit boards so that they are optimized for manufacturing at lowest cost.

General details

| Standard | |

| Maximum circuit size | 508mm X 610mm (20″ X 24″) |

| Number of layers | to 28 layers |

| Pressed thickness | 0.4 mm – 4.0mm |

PCB Materials

As a supplier of various PCB technologies, volumes, lead time options, we have a selection of standard materials with which a large bandwidth of the variety of types of PCB can be covered and which are always available in house.

Requirements for other or for special materials can also be met in most cases, but, depending upon the exact requirements, up to about 10 working days may be needed to procure the material.

Do get in touch with us and discuss your needs with one of our sales or CAM team.

Standard materials held in stock:

| Components | Thickness |

| Internal layers | 0,05mm |

| Internal layers | 0.10mm |

| Internal layers | 0,13mm |

| Internal layers | 0,15mm |

| Internal layers | 0.20mm |

| Internal layers | 0,25mm |

| Internal layers | 0.30mm |

| Internal layers | 0.36mm |

| Internal layers | 0,41mm |

| Internal layers | 0,51mm |

| Internal layers | 0,61mm |

| Internal layers | 0.71mm |

| Internal layers | 0,80mm |

| Internal layers | 1,0mm |

| Internal layers | 1,2mm |

| Internal layers | 1,55mm |

| Prepregs | 0.058mm* |

| Prepregs | 0.084mm* |

| Prepregs | 0.112mm* |

| Prepregs | 0.205mm* |

Cu thickness for internal layers: Standard - 18µm and 35 µm,on request 70 µm, 105µm and 140µm

Material type: FR4

Tg: approx. 150°C, 170°C, 180°C

εr at 1 MHz: ≤5,4 (typical: 4,7) More available on request

Stack up

PCB stack-up is an important factor in determining the EMC performance of a product. A good stack-up can be very effective in reducing radiation from the loops on the PCB, as well as the cables attached to the board.

our factors are important with respect to board stack-up considerations:

| 1. The number of layers, |

| 2. The number and types of planes (power and/or ground) used, |

| 3. The ordering or sequence of the layers, and |

| 4. The spacing between the layers. |

Usually not much consideration is given except as to the number of layers. In many cases the other three factors are of equal importance. In deciding on the number of layers, the following should be considered:

| 1. The number of signals to be routed and cost, |

| 2. Frequency |

| 3. Will the product have to meet Class A or Class B emission requirements? |

Often only the first item is considered. In reality all the items are of critical importance and should be considered equally. If an optimum design is to be achieved in the minimum amount of time and at the lowest cost, the last item can be especially important and should not be ignored.